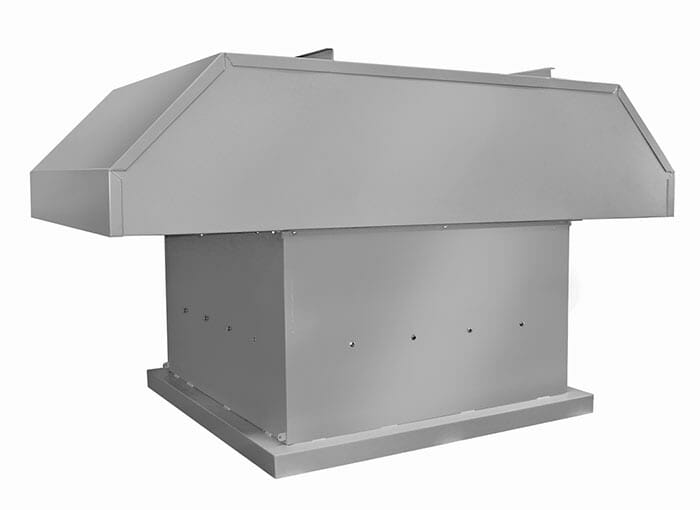

Roof Exhaust Fans

The roof or rooftop exhaust fan is the most efficient way to rid a building or facility of overheated air issues. Since hot air rises to the ceiling or the highest point of a structure, it makes sense that having exhaust fans mounted on the roof will work best. Not all facilities can utilize a roof exhauster due to weight issues, pitch of roof, access to the roof and so on. These fans can be very heavy, and getting the... Read More.

The roof or rooftop exhaust fan is the most efficient way to rid a building or facility of overheated air issues. Since hot air rises to the ceiling or the highest point of a structure, it makes sense that having exhaust fans mounted on the roof will work best. Not all facilities can utilize a roof exhauster due to weight issues, pitch of roof, access to the roof and so on. These fans can be very heavy, and getting them in place on the roof may require a man-lift or crane. since the fan itself is not typically mounted directly to the roof, a curb is usually required and recommended to be flashed to the roof prior to the installation of the fan. This allows the fan to seat properly for effective air removal or exhausting. This is when a wall exhaust fan may be necessary.

We offer commercial roof fans, industrial rooftop exhausters, centrifugal wheel or axial blade upblast or downblast roof exhaust fans for commercial kitchens, schools or hospitals. The upblast rooftop fan ejects the air from the building straight up into the atmosphere, while a downblast roof fan ejects the air downward to the roof by using a bell shaped cap on the top of the fan. The upblast roof mount fan uses a butterfly type damper and rain gutter design so that when the fan is off no rain can enter the building. Whereas the downblast roof exhaust fan does not need the damper due to the bell like housing which keeps all weather out of the building. CFM's for these rooftopf fans range from 550 to 75,000. These roof ventilators come in either belt drive or direct drive versions. The belt drive units are typically quieter, and can usually move air at a higher CFM then the direct drive unit. Rooftop fans with axial blades move more air, but do not work as well with high static pressures. Whereas the centrifugal wheeled fan is typically quieter and works more efficiently where static pressures are moderate to high. Industrial Fans Direct carries several manufactures and brands of roof exhaust fans, such as Canarm Ltd., National Fan Co. and Soler & Palau USA. Call and speak with a knowledgeable sales representative today 866.727.1060.

Read less- AG Cabinet Wall Exhaust

- Agriculture Box Fans

- Agriculture Fans

- Agriculture Panel Fans

- Air Circulator Box Fans

- Air Circulator Panel Fans

- Amazon Listed

- Americraft

- Axial Roof Upblast

- Bathroom Fans

- Best Seller

- Best Seller Fans

- Bitcoin Mining

- Blade 24 inches

- Blade 50 inches

- Blade 8 inches

- Boxed and Slant Wall Exhaust Fans

- Boxed Wall Exhaust Fans for Agriculture

- Boxed Wall Exhaust Fans for Barns

- Cabinet Mounted Wall Exhaust Fans

- Cabinet Mounted Wall Ventilator Fans

- Cabinet Wall Exhaust

- Canarm Exhaust Fans

- Centrifugal Roof Downblast

- Centrifugal Roof Upblast

- Centrifugal Wall Exhaust

- Centrifugal Wall Exhaust Fans

- Commercial Use

- Continental Exhaust Fans

- Corrosion Resistant

- Corrosion Resistant Wall Exhaust Fans

- Corrosion Resistant Wall Ventilator Fans

- Corrosive Environments

- Discount 10

- Discount 7

- Downblast Axial Roof Exhaust Fans

- Downblast Centrifugal Roof Exhaust Fans

- Downblast Centrifugal Roof Ventilator Fans

- Dylam

- Dylam 1

- Dylam 18

- Dylam 19

- Dylam 2

- Dylam 20

- Dylam 21

- Dylam 22

- Dylam 23

- Dylam 3

- Dylam 33

- Dylam 4

- Dylam 5

- Dylam 6

- Dylam 7

- Dylam 8

- Energy Efficient

- Energy Efficient Exhaust Fan

- Energy Efficient Exhaust Fans

- Energy Efficient Roof Exhaust Fans

- Energy Efficient Wall Exhaust Fans

- Energy Exhaust Fans

- Exhaust Fans

- Exterior Wall Exhaust Fans

- Fiberglass Wall Exhaust Fans

- Filtered Wall Exhaust

- Filtered Wall Exhaust Fans

- Filtered Wall Ventilator Fans

- Flange Mounted Wall Exhaust Fans

- Flange Mounted Wall Supply Fans

- FNI

- Freight 1

- Freight 2

- Freight 3

- Freight 5

- Galvanized Coned Wall Exhaust Fans for Agriculture

- Galvanized Coned Wall Exhaust Fans for Barns

- Galvanized Coned Wall Exhaust Fans for Dairies

- General Use

- Guard Mounted Exhaust

- Guard Mounted Wall Exhaust

- Heavy Use

- Hooded Downblast Roof Exhaust Fans

- Industrial Direct

- Industrial Use

- J&D Exhaust Fans

- Large Exhaust Fans

- model: 101298

- model: 101301

- model: 101303

- model: 101305

- model: 101313

- model: 101316

- model: 10sf4v30c

- model: 12sf4t50c

- model: 12sf4v35c

- model: 16sf4v75c

- model: 18sf4v180c

- model: 20sf4t90c

- model: 20sf4v180c

- model: 24d370

- model: 24sf6d240c

- model: 36d370s

- model: 36sf8n370

- model: 48x750s

- model: 8sf4v30c

- model: add16t30050bm

- model: add18t10075b

- model: add36t31000bm

- model: add42t30200dm

- model: are12mm1cs

- model: are16mm1as

- model: ax08-ecv

- model: ax10-ecv

- model: ax12-2

- model: ax12-3

- model: ax12-ec

- model: ax14-1v

- model: ax14-2

- model: ax16-1v

- model: ax16-2

- model: ax16-3

- model: ax18-1v

- model: ax18-2

- model: ax20-1v

- model: ax20-2

- model: ax24-1m

- model: ax36-7

- model: ax36-7m

- model: ce10-dv

- model: ce12-d

- model: ce14-d

- model: ce18-d

- model: ce20-ds

- model: cwd14qm1as

- model: ddar10

- model: ddar14

- model: ddar18

- model: dr33h

- model: dr50h

- model: dr85h

- model: du50h230

- model: du85h

- model: gpx1210

- model: gpx1611

- model: gpx2011

- model: gpx3013

- model: gsf3-12a

- model: hva24t10100

- model: hva36t10150

- model: if14ups

- model: if18ups

- model: if30

- model: if36

- model: n630-c-3-t

- model: n630-e-3-t

- model: n924-h-3-t

- model: n930-h-3-t

- model: n936-i-3-t

- model: n936l-h-3-t

- model: n942l-i-3-t

- model: n960l-i-3-t

- model: nal30-d-1-t

- model: nal30-g-3-t

- model: nal48-j-3-t

- model: nbpv36-i-3-t

- model: nbpv48-ic3t

- model: nbpv60-ic3t

- model: nbpv60-kc3t

- model: nbv18-d-3-t

- model: ncfe16-a-3t

- model: ncfe42-g-3e

- model: p12-1m

- model: p12-1v

- model: p12-2

- model: p12-3

- model: p16-1m

- model: p18-1m

- model: p18-1v

- model: p18-3

- model: p20-1v

- model: p24-1m

- model: p24-1v

- model: p30-2

- model: p36-7

- Model: pf121vhe

- model: pf242

- model: pfm126p13

- model: rb30t30075m

- model: rb36t10300

- model: rb54t30500m

- model: rta18t10150

- model: rta24t30150m

- model: rta36t30200m

- model: rta48t11000

- model: s12-e2

- model: s12-evd

- model: s14-e2

- model: s16-e2

- model: s16-evd

- model: s18-f2

- model: s20-f2

- model: sd10

- model: sd10-ecv

- model: sd12-ec

- model: sd14-ec

- model: sd18-ec

- model: sd20-ec

- model: sd30-g1d

- model: sd36-ec

- model: sd36-g1d

- model: sd8-ecv

- model: sdb06ml1s

- model: sdb14ph1s

- model: sdb14qh1s

- model: sdb22rh1s

- model: sdbd06jh1as

- model: sdbd08hm1as

- model: sdbd08jh1as

- model: sdbd08mh1as

- model: sdbd08mh1cs

- model: sdbd10mm1as

- model: sdbd10ph1as

- model: sdbd12mm1as

- model: sdbd14mm1as

- model: sdbd15qm1as

- model: sdbd16qm1as

- model: sf12e1

- model: sf14e1

- model: sf20f1

- model: sf36g1d

- model: sft-1600

- model: sft-2000

- model: slw4213d

- model: slw4815d-460

- model: stxb14rhulrh1s

- model: stxb15rhulrh1s

- model: stxb20rhulqh1s

- model: stxb24rhulvh1s

- model: stxd08hm1as

- model: swf150

- model: swf200

- model: tf12

- model: tf16

- model: tf18

- model: tf24

- model: usprn1000026

- model: usprn135ec0022

- model: v2412-v

- model: v2e30k1m71100

- model: v2e35k2m71100

- model: v3022

- model: v3023

- model: v4213-v

- model: v4813-v

- model: v4813-x

- model: v4814-u

- model: v4d30k1m71100

- model: v4d35k4m71100

- model: v4d40k2m71100

- model: v4d45k2m71100

- model: v4e13k2m11036

- model: v4e25k2m72100

- model: v4e30k1m71100

- model: v4e40k1m71100

- model: v4e40k2m71100

- model: v4e45k2m71100

- model: v4e50k2m71100

- model: v4e63k1m71100

- model: v6d63k7m71100

- model: v6e63k1m71100

- model: v6e63k2m71100

- model: vcn 125

- model: ves10c

- model: ves20

- model: ves201c

- model: ves24

- model: ves243a

- model: ves30

- model: ves303

- model: ves30c

- model: vf36dm

- model: vf36gg

- model: vf36gg1

- model: vf36gg2

- model: vf36gg3

- model: vf50gg

- model: vf50gg6

- model: vfa50a3

- model: vfa50ac3

- model: vfp12p

- model: vfp16a

- model: vfp20p-gs

- model: vfp36gc-gs

- model: vfp36gc3

- model: vfs24cs

- model: vfs503csca

- model: vfs50cs26

- model: vfs50cs3

- model: vft141130

- model: vft141131

- model: vft141133

- model: vi2412-x

- model: vi2413-v

- model: vi2413t-x

- model: vi3012-w

- model: vi3014-u

- model: vi3014t-x

- model: vi3613-x

- model: vi4215-x

- model: vi4815-x

- model: vi4816-x

- model: vi6018-x

- model: vid4815t-x

- model: vik3013-v

- model: vik3613-v

- model: vik4213-v

- model: vik4213-x

- model: vik4215-u

- model: vik4216-u

- model: vik4216t-x

- model: vik4814-x

- model: vik4814t-x

- model: vik4815-u

- model: vik4817-x

- model: vik4818-u

- model: vik4819-x

- model: vik5417-u

- model: vp36d

- model: vsp55a3c21

- model: xb30t10075

- model: xb36t30200m

- model: xb48t10100

- model: xb48t10150

- model: xb54t10150

- model: xbl42t10075

- model: xbl48t10100

- model: xfs24

- model: xsa105-dd013v

- model: xsa120-ud033v

- model: xsa135-ud050v

- model: xsa150-dd075s

- model: xsa210-ud100ec

- model:add36t30200cm

- model:afk-24-a255a06-05-32

- model:afk-27-a255a06-05-32

- model:afk-30-a255a06-10-32

- model:afk-36-a255a06-10-32

- model:ax12-1v

- model:ax20-3

- model:ax24-1v

- model:ax24-2

- model:ax30-2

- model:ax42-7

- model:ce10-ds

- model:ce12-ds

- model:ce12-dv

- model:ce14-ds

- model:ce16-ds

- model:ce18-ds

- model:ce24-ds

- model:ce30-ds

- model:cwd07hh1as

- model:cwd10ph1as

- model:ddar12

- model:gpx2413

- model:n624-c-3-t

- model:n948l-i-3-t

- model:nbpv36-h-3-t

- model:p14-1m

- model:p14-1v

- model:p16-1v

- model:p24-2

- model:rb48t30750m

- model:s12-e1

- model:s14-e1

- model:s16-e1

- model:s18-f1

- model:s18-fvd

- model:s20-f1

- model:sd08

- model:sd24-f1

- model:sd24-gvd

- model:sd42-h1d

- model:sd48-h1d

- model:sdbd07jh1as

- model:sdbd12qh1as

- model:v2422

- model:v2e25k1m72100

- model:v4e30k2m71100

- model:v4e35k4m71100

- model:v6e56k0m71100

- model:v6e71k0m71100

- model:vcn 150

- model:vcn-200

- model:ves12

- model:ves12c

- model:ves161

- model:ves161c

- model:ves20c

- model:ves24c

- model:vf36dm3cf

- model:vf503gg

- model:vi3613-v

- model:vi4213-v

- model:vi4814-u

- model:vi5417-x

- model:vik4814-u

- model:vik6019-x

- model:vmsa72a5n33

- model:vpes12

- model:vpes16

- model:vpes20

- model:xb60t30200m

- model:xfs12

- model:xfs16

- model:xfs20

- model:xsa150-ud075s

- Multifan Exhaust Fans

- NFC Exhaust Fans

- No Low Price

- Outdoor Rated Exhaust Fans

- Outdoor Rated Fans UL507 Listed

- Panel Mount Wall Exhaust

- Panel Mounted Wall Exhaust Fans

- Panel Wall Exhaust

- Poly & Fiberglass Agriculture Fans

- Poly and Fiberglass Wall Exhaust Fans for Agriculture

- Poly and Fiberglass Wall Exhaust Fans for Barns

- Poly and Fiberglass Wall Exhaust Fans for Dairies

- Quiet Exhaust Fans

- Roof Exhaust Fans

- RTA Axial Roof Upblast

- RTA Upblast Axial Roof Exhaust Fans

- Shutter Mounted Wall Exhaust

- Shutter Mounted Wall Exhaust Fans for Agriculture

- Shutter Mounted Wall Exhaust Fans for Barns

- Shutter Mounted Wall Exhaust Fans for Dairies

- Shuttered Mounted Wall Exhaust

- Shuttered Wall Mounted Exhaust Fans

- Shuttered Wall Mounted Ventilator Fans

- Side Wall Exhaust Fans

- Sidewall Exhaust Fans

- Slant Wall Exhaust Fans for Agriculture

- Slant Wall Exhaust Fans for Barns

- Slant Wall Exhaust Fans for Dairies

- Special Build

- Stainless Panel Wall Exhaust

- Thru Wall Exhaust Fans

- TN Exhaust Fans Fiberglass Wall

- TN Exhaust Fans Filtered Wall

- TN Exhaust Fans Roof

- TN Exhaust Fans Wall

- TN Industrial Agriculture

- TN Warehouse Roof Exhaust

- TN Warehouse Wall Exhaust

- Tracked

- U.S. Fan

- U.S. Fan Exhaust Fan

- Upblast Axial Roof Exhaust Fans

- Upblast Axial Roof Ventilator Fans

- Upblast Centrifugal Roof Exhaust Fans

- Upblast Centrifugal Roof Ventilator Fans

- USA

- Wall Exhaust Fans

Loading...

Loading...