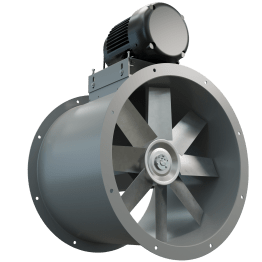

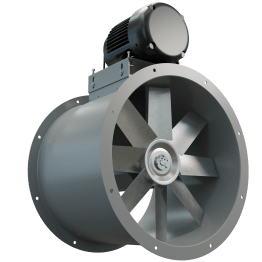

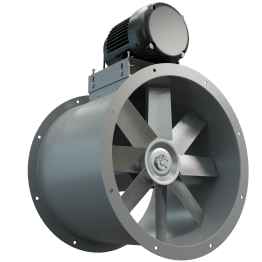

RAPTOR -NB Tube Axial Fan 12 inch 1875 CFM Belt Drive NB12-C-1-T

RAPTOR -NB Tube Axial Fan 12 inch 1444 CFM Belt Drive 3 Phase NB12-A-3-T

RAPTOR -NB Tube Axial Fan 12 inch 1444 CFM Belt Drive NB12-A-1-T

RAPTOR -NB Tube Axial Fan 12 inch 2044 CFM Belt Drive NB12-D-1-T

RAPTOR -NB Tube Axial Fan 12 inch 2044 CFM Belt Drive 3 Phase NB12-D-3-T

RAPTOR -NB Tube Axial Fan 15 inch 3350 CFM Belt Drive 3 Phase NB15-C-3-T

RAPTOR -NB Tube Axial Fan 12 inch 1586 CFM Belt Drive 3 Phase NB12-B-3-T

RAPTOR -NB Tube Axial Fan 12 inch 1586 CFM Belt Drive 1 Phase NB12-B-1-T

RAPTOR -NB Tube Axial Fan 12 inch 1875 CFM Belt Drive 3 Phase NB12-C-3-T

RAPTOR -NB Tube Axial Fan 15 inch 3350 CFM Belt Drive NB15-C-1-T

RAPTOR -NB Tube Axial Fan 15 inch 3900 CFM Belt Drive 1 Phase NB15-D-1-T

RAPTOR -NB Tube Axial Fan 15 inch 3900 CFM Belt Drive 3 Phase NB15-D-3-T

RAPTOR -NB Tube Axial Fan 15 inch 2600 CFM Belt Drive 3 Phase NB15-A-3-T

RAPTOR -NB Tube Axial Fan 15 inch 2600 CFM Belt Drive 1 Phase NB15-A-1-T

RAPTOR -NB Tube Axial Fan 18 inch 3850 CFM Belt Drive 3 Phase NB18-C-3-T

RAPTOR -NB Tube Axial Fan 18 inch 3050 CFM Belt Drive 3 Phase NB18-A-3-T

RAPTOR -NB Tube Axial Fan 18 inch 3050 CFM Belt Drive 1 Phase NB18-A-1-T

RAPTOR -NB Tube Axial Fan 15 inch 2950 CFM Belt Drive 3 Phase NB15-B-3-T

RAPTOR -NB Tube Axial Fan 15 inch 2950 CFM Belt Drive 1 Phase NB15-B-1-T

RAPTOR -NB Tube Axial Fan 18 inch 3850 CFM Belt Drive NB18-C-1-T

RAPTOR -NB Tube Axial Fan 18 inch 3375 CFM Belt Drive 3 Phase NB18-B-3-T

RAPTOR -NB Tube Axial Fan 18 inch 3375 CFM Belt Drive 1 Phase NB18-B-1-T

BTA Tube Axial Fan 15 inch 3324 CFM Belt Drive BTA15T10075

RAPTOR -NB Tube Axial Fan 24 inch 5643 CFM Belt Drive 3 Phase NB24-C-3-T

BTA Tube Axial Fan 15 inch 3620 CFM Belt Drive 3 Phase BTA15T30075M

RAPTOR -NB Tube Axial Fan 18 inch 4600 CFM Belt Drive 3 Phase NB18-E-3-T

RAPTOR -NB Tube Axial Fan 24 inch 5643 CFM Belt Drive 1 Phase NB24-C-1-T

RAPTOR -NB Tube Axial Fan 24 inch 6906 CFM Belt Drive 1 Phase NB24-D-1-T

RAPTOR -NB Tube Axial Fan 24 inch 6906 CFM Belt Drive 3 Phase NB24-D-3-T

BTA Tube Axial Fan 12 inch 1650 CFM Belt Drive BTA12T10075A

RAPTOR -NB Tube Axial Fan 18 inch 5350 CFM Belt Drive 3 Phase NB18-F-3-T

RAPTOR -NB Tube Axial Fan 24 inch 7425 CFM Belt Drive 3 Phase NB24-E-3-T

RAPTOR -NB Tube Axial Fan 18 inch 4600 CFM Belt Drive NB18-E-1-T

BTA Tube Axial Fan 18 inch 5441 CFM Belt Drive 3 Phase BTA18T30200M

BTA Tube Axial Fan 12 inch 2138 CFM Belt Drive 3 Phase BTA12T30075M

BTA Tube Axial Fan 18 inch 4161 CFM Belt Drive 3 Phase BTA18T30100M

BTA Tube Axial Fan 15 inch 4000 CFM Belt Drive 3 Phase BTA15T30100M

RAPTOR -NB Tube Axial Fan 24 inch 7425 CFM Belt Drive NB24-E-1-T

BTA Tube Axial Fan 18 inch 4884 CFM Belt Drive BTA18T10150

RAPTOR -NB Tube Axial Fan 18 inch 5350 CFM Belt Drive 1 Phase NB18-F-1-T

BTA Tube Axial Fan 18 inch 4680 CFM Belt Drive BTA18T10075B

BTA Tube Axial Fan 18 inch 4680 CFM Belt Drive 3 Phase BTA18T30075M

RAPTOR -NB Tube Axial Fan 30 inch 8900 CFM Belt Drive 3 Phase NB30-C-3-T

BTA Tube Axial Fan 24 inch 6119 CFM Belt Drive 3 Phase BTA24T30100M

BTA Tube Axial Fan 18 inch 4161 CFM Belt Drive BTA18T10100

RAPTOR -NB Tube Axial Fan 30 inch 8900 CFM Belt Drive 1 Phase NB30-C-1-T

BTA Tube Axial Fan 24 inch 6973 CFM Belt Drive BTA24T10150

BTA Tube Axial Fan 12 inch 2138 CFM Belt Drive BTA12T10075

How Do I Select the Right Tube Axial Belt Drive Exhaust Fan for My Facility?

Choosing the correct tube axial fan starts with understanding your facility's specific airflow requirements. CFM (Cubic Feet per Minute) is the critical specification that determines whether a fan can adequately ventilate your space. Calculate your needs based on room volume and the number of air changes per hour required for your application. Manufacturing environments with airborne particulates or fumes typically require 10 to 15 air changes per hour, while general warehouse ventilation may need 6 to 10. You can also use our CFM calculator to estimate your specific airflow requirements.

Belt drive configurations offer a significant advantage over direct drive models because you can adjust fan speed by changing pulley sizes. This means a single tube axial duct fan can be adapted to meet varying static pressure requirements or to optimize energy consumption for your specific ductwork layout. Our product listings include detailed performance curves showing CFM output at different static pressures, allowing you to match fan capabilities to your ventilation system's resistance. If your application calls for moving air into a space rather than exhausting it, consider a supply fan configuration instead.

What Are the Maintenance and Long-Term Operating Considerations?

Belt drive exhaust fans require periodic maintenance that direct drive units do not, but this trade-off comes with meaningful benefits. Belt and pulley systems allow for speed adjustments without replacing the motor, and the belt acts as a buffer that protects the motor from shock loads. Plan for belt inspections every 3 to 6 months and replacement annually under typical operating conditions.

Motor positioning in belt drive designs places the motor outside the airstream in most configurations. This separation protects the motor from corrosive or high-temperature exhaust air, extending motor life in demanding applications like paint booths, welding shops, or chemical processing areas. When evaluating total cost of ownership, factor in the extended motor lifespan and the ability to fine-tune performance without purchasing a different fan entirely. Many facility managers find that the flexibility and durability of belt drive systems justify the modest maintenance requirements.

What Performance and Durability Features Should I Prioritize?

Industrial exhaust applications demand axial fans built to withstand continuous operation in challenging environments. Look for tube axial belt drive exhaust fans with heavy-gauge steel housings, cast aluminum or steel propellers, and sealed bearings rated for extended service intervals. Propeller material matters: aluminum resists corrosion and offers excellent balance for smooth operation, while steel propellers handle higher temperatures and abrasive conditions.

Motor quality directly impacts reliability and operating costs. Premium motors with Class F or Class H insulation withstand higher temperatures, reducing the risk of burnout during peak demand periods. Thermal overload protection provides an additional safety layer by automatically shutting down the motor before heat damage occurs. Our collection includes fans rated for continuous duty operation, meaning they are engineered to run 24/7 without the cycling limitations found in lighter-duty equipment. Check individual product specifications for temperature ratings if your application involves exhausting heated air from ovens, dryers, or process equipment.

Why Shop at Industrial Fans Direct for Tube Axial Belt Drive Exhaust Fans?

Industrial Fans Direct has spent more than 20 years building relationships with leading manufacturers and supporting customers across manufacturing, warehousing, and commercial sectors. Our sales team works on a non-commission basis, which means you receive honest recommendations focused on solving your ventilation challenge. We stand behind our pricing with a Low Price Guarantee.

Beyond competitive pricing, you gain access to knowledgeable support from people who understand industrial ventilation. Whether you need a high velocity fan for aggressive air movement, inline duct fans for integrated HVAC systems, or industrial wall fans for spot ventilation, we help mechanical contractors, engineers, and facility managers select equipment that fits the application. Browse our full catalog to find related solutions including duct fans, air circulators, and air curtains. When you need an axial fan that performs reliably and a supplier that treats your project as a partnership, Industrial Fans Direct delivers both.